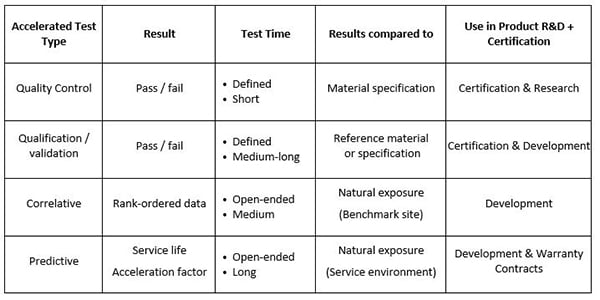

A very common and fundamental question to ask when beginning a weathering and/or corrosion testing program: “What kind of accelerated test should I run?” It’s a critical question to answer, but there isn’t one general answer that covers all customer situations. The matrix shown below illustrates four different “tiers” of accelerated weathering and corrosion testing. Each is distinguished by the type of information it delivers, typical length of testing, basis for comparison, and what kind of a research and development or certification program the test might be used for.

The quality control and qualification/validation tests give pass/fail data that is typically used as screening tools. Correlative testing produces rank-ordered data that can be compared to outdoor results. Predictive testing can indicate material service life but is highly material-and service environment-specific. All of these tiers of testing serve as directional decision-making tools – techniques to help customers make informed decisions on what materials and systems to pursue and how to lower the risk associated with those products.